Our manufacturing facility of Chandi Polymers Pvt. Ltd. is spread With state of the art infrastructure and modern facilities, our premises is well-equipped with top of the line plant & machineries capable of producing unparallel quality of products which makes us one of the top-tier manufacturers. Being highly committed towards growing our business facility and services lining with our strategic vision, we are always engaged with new technologies. At present, we are equipped with:

TAPE LINE

➢ Lohia Corp make, Lorex E120B 1400HS – Installed with semi-automatic Cheese Winder LFW 200CM with melting capacity 600 kg/hr translating to 300 MT/month

➢ Lohia Corp make, Lorex E105B 1600HS – Installed with semi-automatic Cheese Winder LFW 200CM with melting capacity 600 kg/hr translating to 300 MT/month

CIRCULAR LOOMS

➢ 105 nos. in total, all of Lohia Corp make – Lates t model Nova 6 and LSL6 capable of producing 8 million meters of fabric from 15” to 56” in flat/tubular form.

EXTRUSION LAMINATION

➢ JP Extrusiontech make – 30” width tandem extrusion i.e. both sides at once allowing faster production.

PRINTING MACHINES

➢ Polygraph –Flexographic printing machine with Corona treatment suitable for printing on PP, H.M. HDPE, Polyester, Foil or paper

PRINTING MACHINES

➢ Starflex Industries –Flexographic printing machine with Corona treatment suitable for printing on PP, H.M. HDPE, Polyester, Foil or paper

STITCHING MACHINES

➢ Armstrong & Gabber ST-502 HD make, each capable of producing 20000 bags/day

STITCHING MACHINES

➢ Lohia Corp make, automatic BCS, capable of stitching 40000 bags/day

PRINTING MACHINES

➢ Navjivan Exporters – Drum printing machine, capable of 1/2 colors printing

TWIST GUSSET UNIT

Twist / Shift Gusset unit is a pioneering development which has been done by SIMPLEX specifically bearing in mind the

requirement of BOPP Bag manufacturers. This has become an essential requirement looking at the market demand of high quality, wrinkle free BOPP Gusseted Bags. Following are few of the many benefits of In-line Twist / Shift Gusset Unit:

➢ In-line Gusset Formation while making Bags on BCS will result in man-power saving.

➢ One single process – eliminate one extra operation.

➢ Resulting in space saving.

➢ Produce accurate, good looking &better-quality bags

STITCHING MACHINES

➢ MAQI LS-0303 Zipper Bags Make, Each Capable of Producing 300 Bags/day ➢ PRECIOUS LS-0303 Zipper Bags Make, Each Capable of Producing 300 Bags/day

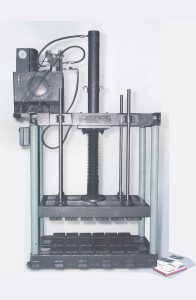

BALING MACHINE

Baling Machine of HDPE / PP Woven sack, Jute bags and laminated jute bags, Paper waste, Cotton, Coir Paddy straw etc. Is a major application for which NAVJIVAN Baling Press has been designed. maximum and different compressive forces from 30 ton to 80 ton.